LOADING...

LOADING...

SEALTECH has advanced technologies of hermetic seals, Glass/Ceramics to Metals, Metalized ceramics and Brazing, etc. SEALTECH products hermetically sealed between glass and metal, and ceramic and metal or glass, perform in the harsh environments with excellent insulation resistance, high vacuum, pressure withstanding, temperature withstanding, leak tightness and anti-corrosion.

All hermetic seals manufactured by SEALTECH meet or exceed the following general requirements.

GTM Sealing refers to a technology of sealing and fusion bonding glass(ceramics) to metals at high temperatures. Glass-to-metal seals provide a way to hermetically pass an electrical conductor from one environment to another. The glass not only provides sealing but acts as an insulator between pins and housing which protect devices and transmit signals in the harsh environments. These conductor feedthroughs can be used for many applications such as: vacuum components, sensor or transducer housings, feedthroughs, etc.

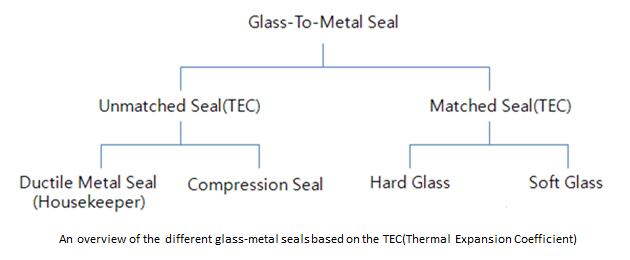

Today, Glass to Metal hermetic seals available in various industries are generally divided by two types. These are matched seal (parts with similar coefficients of thermal expansion) and unmatched seals (parts with different coefficients of thermal expansion).

To create a matched seal, housing and glass materials are selected to have similar coefficient of thermal expansion. The strength of a matched seal comes primarily from a chemical bond between the glass and an oxide formed on the metal parts. Matched seals are most often made with Ni alloy, Kovar(Ni-Co Alloy) housings and pins, and borosilicate glass.

A unmatched(compression) seal is made of a much higher thermal expansion rate of housing material than that of the glass. Upon solidification of the seal during the manufacturing process, the housing will contract around the glass, applying a desirable compression stress on the glass bead. The during the manufacturing process, the housing will contract around the glass, applying a desirable compression stress on the glass bead. The strength of the glass to metal seal is reinforced mechanically as well as chemically, creating a stronger, more reliable part. Compression seals are often made using steel or stainless steel housings,nickel iron pins, and barium alkali glass.